Product Categories

-

Coffee Table

Coffee table is a low table used in living room or lounge...

-

Side Table

Side table is a small table usually placed next to the sofa...

-

Dinning Table

Dining table is a piece of furniture used for eating at home...

-

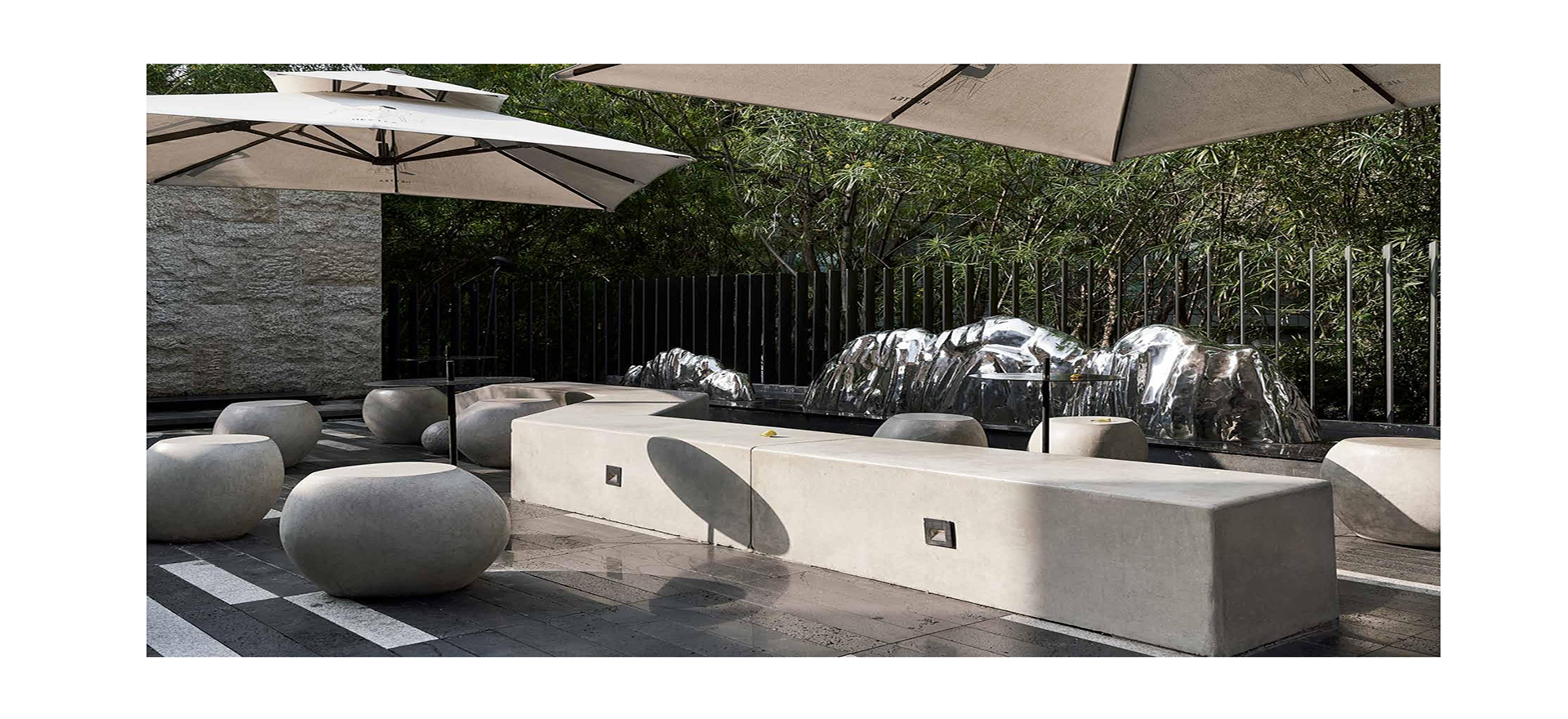

Stool and Bench

Stool typically consists of a single seat supported by either legs or...

-

Console Table

Console table is a narrow and typically tall piece of furniture designed...

Why you can trust LIONZCONCRETE?

-

Experience and Expertise

Since its inception in 2008, LIONZCONCRETE has emerged as a cornerstone in the international furniture manufacturing landscape. Our fifteen-year trajectory is marked by relentless innovation, mastering state-of-the-art techniques, materials, and technology to redefine industry standards.

-

Professional team

Our pride lies in our team of about 110 skilled artisans, whose unparalleled craftsmanship and commitment to quality elevate our work beyond conventional scrutiny, ensuring every piece resonates with our ethos of excellence. This formidable expertise allows us to boast an impressive annual production capacity, with around 350 containers of contemporary, premium furniture ready to meet the global demands of modern living spaces.

-

Reputation and Trust

With a decade and a half of operations under your belt, LIONZCONCRETE has likely built a strong reputation for reliability, quality, and customer satisfaction. Satisfied customers who have purchased ours furniture over the years can become repeat buyers and advocates for LIONZCONCRETE.

-

Product quality control

LIONZCONCRETE factory needs to ensure that the product quality meets the standards and customer expectations, and needs to establish a strict quality control system. From raw material procurement to production and processing, to the inspection and packaging of the final product, our factory needs to strictly control each link to ensure stable and reliable product quality.

Order process:

- send product photos

- 3D modeling

- sweep swatches (materials) (10 days)

- pay the sample fee

- prepare the mold ( mold type → samples) (30 days)

- confirm the sample

- place an order

Product processing flow

1.Product mold making.

2.Paint the first layer of cement mortar (surface mortar) in the mold by hand.

3.Spreading connecting slurry (thin slurry).

4.Spreading appropriate amount of reinforced fiber on the connecting slurry.

5.Spreading mortar on the fiber filament, so that the cement paste and fiber fully adhered to.

6.To be compacted before the cement is first set and polished.

7.Products to be dry after sanding, repair, to ensure that the product is smooth, smooth.

After the product is repaired, spray outdoor water-based varnish, the product is finished.

Blog posts

View all-

5 Benefits of Having Concrete Furniture

Concrete furniture is becoming an increasingly popular choice for both indoor and outdoor spaces, and it’s easy to see why. This versatile material offers a unique blend of durability, style,...

5 Benefits of Having Concrete Furniture

Concrete furniture is becoming an increasingly popular choice for both indoor and outdoor spaces, and it’s easy to see why. This versatile material offers a unique blend of durability, style,...

-

The Best Materials to Use for Outdoor Garden: C...

When designing an outdoor garden, selecting the right materials is crucial for creating a space that is not only beautiful but also durable and functional. Among the various materials available,...

The Best Materials to Use for Outdoor Garden: C...

When designing an outdoor garden, selecting the right materials is crucial for creating a space that is not only beautiful but also durable and functional. Among the various materials available,...

-

How to Choose the Perfect Concrete Furniture fo...

Concrete furniture has become a popular choice for modern homes, offering a unique blend of durability, style, and functionality. Whether you're looking to add an industrial edge to your living...

How to Choose the Perfect Concrete Furniture fo...

Concrete furniture has become a popular choice for modern homes, offering a unique blend of durability, style, and functionality. Whether you're looking to add an industrial edge to your living...